Locking tubes

Order Monday-Thursday before 15:30 and Friday before 14:45 and we’ll dispatch your order the same day with expected delivery within 2-4 days. This applies to all stocked rubber bellows

See quantity discounts and prices by clicking on the shopping cart next to the required product. Use the range sliders below for quick and easy navigation.

A locking tube is used as a safety device in structures with gas springs. The locking tube stops the gas spring closing unexpectedly. This may be in the event of a gust of wind, distortion of the gas spring, a leaking gasket, increased load on the structure, etc.

Note: Locking tubes can only be used together with gas springs with threads.

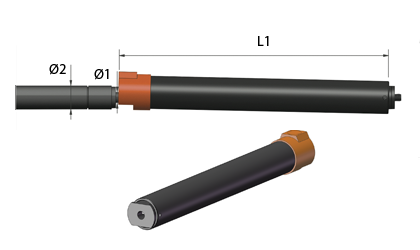

The black version of the locking tube has been given an epoxy powder coating. This provides a degree of rust protection.

If you need to use a locking tube in a wet or damp environment, however, we recommend that you use the stainless steel version.

Used in constructions that are exposed to harsh cleaning agents or in maritime environments

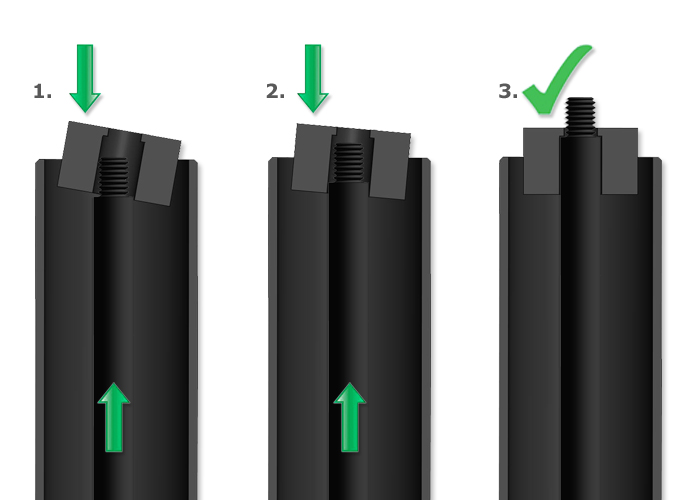

The piston rod of the gas spring must be inserted into the locking tube and the thread must pass through the hole in the end of the locking tube. You can tilt the plate at the bottom so that it is easier to get the thread through. Then screw the end-fitting on. The tilt function will always try to make the tube strike against the piston rod and so prevent the gas spring from closing unexpectedly, as the cylinder will strike the edge of the locking tube and the movement will be stopped. Before closing the door – i.e. before the gas spring can be compressed – the locking tube must be released by pushing it out of the piston rod so that the cylinder can move freely into the locking tube.

42-70023-description

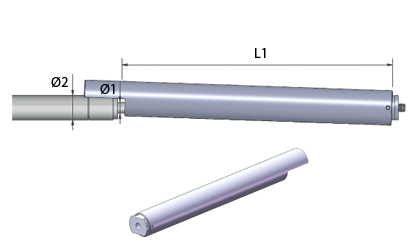

Stainless steel 304

42-70024-description

Stainless steel 316

42-70021-description

Black painted steel

- LTN-6-80In stock: 109Material Black painted steelØ1 - Fits rod size (mm) 6.00Ø2 - Fits cylinder (mm) 15.00L1 - Fits stroke length (mm) 80.00

- LTN-6-100In stock: 89Material Black painted steelØ1 - Fits rod size (mm) 6.00Ø2 - Fits cylinder (mm) 15.00L1 - Fits stroke length (mm) 100.00

- LTN-6-150In stock: 88Material Black painted steelØ1 - Fits rod size (mm) 6.00Ø2 - Fits cylinder (mm) 15.00L1 - Fits stroke length (mm) 150.00

- LTN-6-200In stock: 83Material Black painted steelØ1 - Fits rod size (mm) 6.00Ø2 - Fits cylinder (mm) 15.00L1 - Fits stroke length (mm) 200.00

- LTN-8-100In stock: 85Material Black painted steelØ1 - Fits rod size (mm) 8.00Ø2 - Fits cylinder (mm) 18.00L1 - Fits stroke length (mm) 100.00

- LTX-8-100-316In stock: 137Material Stainless steel 316Ø1 - Fits rod size (mm) 8.00Ø2 - Fits cylinder (mm) 18.00L1 - Fits stroke length (mm) 100.00

- LTX-8-140-316In stock: 137Material Stainless steel 316Ø1 - Fits rod size (mm) 8.00Ø2 - Fits cylinder (mm) 18.00L1 - Fits stroke length (mm) 140.00

- LTN-8-150In stock: 297Material Black painted steelØ1 - Fits rod size (mm) 8.00Ø2 - Fits cylinder (mm) 18.00L1 - Fits stroke length (mm) 150.00

- LTX-8-150-316In stock: 19Material Stainless steel 316Ø1 - Fits rod size (mm) 8.00Ø2 - Fits cylinder (mm) 18.00L1 - Fits stroke length (mm) 150.00

- LTN-8-200In stock: 368Material Black painted steelØ1 - Fits rod size (mm) 8.00Ø2 - Fits cylinder (mm) 18.00L1 - Fits stroke length (mm) 200.00

Black steel

The black version is epoxy powder coated and thus resistant to corrosion.

Stainless Steel - AISI 304

If you need to use a locking tube in a wet or damp environment, however, we recommend that you use the stainless steel version.

Stainless steel - AISI 316

Used in constructions that are exposed to harsh cleaning agents or in maritime environments

The locking tube ensures that external elements such as wind, collisions, impacts, etc. do not cause a gate, for example, to close accidentally, risking injury to people or damage to property.

The function of the locking tube is easily neutralised with just one push.

- When fitting the locking tube onto the gas spring it can be difficult to get the thread on the piston through the end piece of the locking tube. This is because of the spring-loaded end piece, which flips to the side to ensure correct spring function once.

- This is because of the spring-loaded end piece, which flips to the side to ensure correct spring function once.

- Press on the highest point of the end piece, and at the same time guide the piston through the hole in the end piece. Gas springs with a 6 mm piston are screwed into the end piece.

- The locking tube has now been fitted correctly, and the end fitting can be put on.