Extension Springs | Produced In Stainless Steel

Range A&B. Over 1,000 dimensions in stock. All extension springs produced of the highest quality in Europe and America.

Find the correct dimensions by using the filters underneath. Open the filters by clicking the downward arrow.

If you know the stock-number, please write it in the search box at the top of the page.

See quantity discount by clicking on the green basket next to the item.

We can deliver within 24 hours, if you order before 15:45 from Monday till Thursday and before 14:30 on Fridays, if the item is in stock. Orders placed Saturday and Sunday are being shipped the following Monday.

Range A&B. This range consists of two different series. Due to differing dimensions, the two series complement each other. We have therefore opted to combine them into one range .Series A is a European standard, while series B is an American standard. Both series are of the highest quality and both listed in metrics.

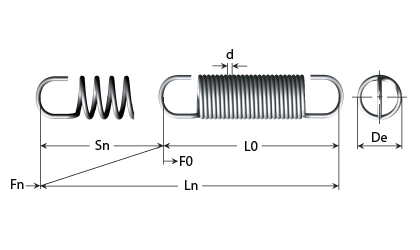

- E00630070250SIn stock: 352Material Stainless steel 302d - Wire diameter (mm) 0.18De - External diameter (mm) 1.60L0 - Unloaded length (mm) 6.35Ln - Max. loaded length (mm) 13.72Sn - Maximum travel (mm) 7.37Fn - Maximum load at Ln (N) 1.19F0 - Initial force (N) 0.11R - Spring constant (N/mm) 0.15Range B

- E00630070310SIn stock: 1,102Material Stainless steel 302d - Wire diameter (mm) 0.18De - External diameter (mm) 1.60L0 - Unloaded length (mm) 7.87Ln - Max. loaded length (mm) 18.54Sn - Maximum travel (mm) 10.67Fn - Maximum load at Ln (N) 1.19F0 - Initial force (N) 0.11R - Spring constant (N/mm) 0.10Range B

- E00630070380SIn stock: 993Material Stainless steel 302d - Wire diameter (mm) 0.18De - External diameter (mm) 1.60L0 - Unloaded length (mm) 9.65Ln - Max. loaded length (mm) 23.62Sn - Maximum travel (mm) 13.97Fn - Maximum load at Ln (N) 1.19F0 - Initial force (N) 0.11R - Spring constant (N/mm) 0.07Range B

- E00630070440SIn stock: 235Material Stainless steel 302d - Wire diameter (mm) 0.18De - External diameter (mm) 1.60L0 - Unloaded length (mm) 11.18Ln - Max. loaded length (mm) 28.45Sn - Maximum travel (mm) 17.27Fn - Maximum load at Ln (N) 1.19F0 - Initial force (N) 0.11R - Spring constant (N/mm) 0.06Range B

- E00630070500SIn stock: 63Material Stainless steel 302d - Wire diameter (mm) 0.18De - External diameter (mm) 1.60L0 - Unloaded length (mm) 12.70Ln - Max. loaded length (mm) 33.27Sn - Maximum travel (mm) 20.57Fn - Maximum load at Ln (N) 1.19F0 - Initial force (N) 0.11R - Spring constant (N/mm) 0.06Range B

- E00630080250SIn stock: 479Material Stainless steel 302d - Wire diameter (mm) 0.20De - External diameter (mm) 1.60L0 - Unloaded length (mm) 6.35Ln - Max. loaded length (mm) 11.68Sn - Maximum travel (mm) 5.33Fn - Maximum load at Ln (N) 1.67F0 - Initial force (N) 0.15R - Spring constant (N/mm) 0.29Range B

- E00630080310SIn stock: 533Material Stainless steel 302d - Wire diameter (mm) 0.20De - External diameter (mm) 1.60L0 - Unloaded length (mm) 7.87Ln - Max. loaded length (mm) 15.24Sn - Maximum travel (mm) 7.37Fn - Maximum load at Ln (N) 1.67F0 - Initial force (N) 0.15R - Spring constant (N/mm) 0.20Range B

- E00630080380SIn stock: 291Material Stainless steel 302d - Wire diameter (mm) 0.20De - External diameter (mm) 1.60L0 - Unloaded length (mm) 9.65Ln - Max. loaded length (mm) 19.05Sn - Maximum travel (mm) 9.40Fn - Maximum load at Ln (N) 1.67F0 - Initial force (N) 0.15R - Spring constant (N/mm) 0.16Range B

- E00630080440SIn stock: 41Material Stainless steel 302d - Wire diameter (mm) 0.20De - External diameter (mm) 1.60L0 - Unloaded length (mm) 11.18Ln - Max. loaded length (mm) 23.11Sn - Maximum travel (mm) 11.93Fn - Maximum load at Ln (N) 1.67F0 - Initial force (N) 0.15R - Spring constant (N/mm) 0.13Range B

- E00630080500SIn stock: 91Material Stainless steel 302d - Wire diameter (mm) 0.20De - External diameter (mm) 1.60L0 - Unloaded length (mm) 12.70Ln - Max. loaded length (mm) 26.67Sn - Maximum travel (mm) 13.97Fn - Maximum load at Ln (N) 1.67F0 - Initial force (N) 0.15R - Spring constant (N/mm) 0.10Range B

DIN 17224 AISI 302 WERKSTOFF NO. 1.4310

Working temperature between -200 ºC and +250 ºC.

Produced in stainless steel for use in all environment. The stainless steel is rust-resistant.

Range A: (The A Range consists of springs with 5 digits, ie: "32200")

All dimensions and forces in accordance with DIN 2097 (Grade 2). DIN 2097 defines the force as the determining parameter. The number of coils may therefore vary and is consequently not stated for these ranges.

Range B: (The B Range consists of springs with 11 digits and 2 letters, ie: "E03600552000M")

For more information, see our FAQ page

Fn for stainless steel spring steel is approx. 0.88 x Fn for music wire.

Calculation of the initial force (F0):

The initial force F0 or the initial tension is for guidance only due to differing production processes.

F0 = Fn - (R * Sn). A rule of thumb is however that F0 is 10-15% of Fn.

For example, for stock number 32600, Fn = 237 N, R = 2,67N/mm og Sn = 75,70mm. F0 = 237N - (2,67N/mm * 75,70mm) = 237N - 202N = 35N

The calculation of spring force for a given length:

Calculation of spring force at a given length is: F0 + (travel * R).

For example, for stock number 32600 where R = 2.67 N/mm, the desired travel is 55 mm and F0 is approx. 35 N. 35N + (55mm * 2,67N/mm) = 35N + 147N = 182N

Range A: Closed German loops in accordance with DIN 2097, random angle.

Tolerance at loop height (LH) is from 0.8 to 1.1 * Dm. The loop position (X) is variable and the loops can therefore be turned in relation to one another. The diameter of loops may well exceed the external diameter of the body. The tolerance for deviations is determined based on the definition below.

Example: Stock number 32600 has a wire thickness of 2.5 mm. The external diameter is 18 mm, which produces a mean diameter of 15.5 mm. From the table above, we can determine how wide the loop must be. First we must work out the coil ratio using the formula Dm/d. The loop width can then be determined using the table above.

Coil ratio: 15.5 mm/2.5 mm = 6.2 mm

Loop width: 18 mm + (1.5 * 2.5 mm) = 21.75 mm

Range B: Loops in this range are closed loops without a specific loop shape and with a random angle. Every effort is made to keep the same external diameter as the spring body. However, the external diameter of the loop may vary.

Normally right-handed

Standard springs are not defined with a specific direction of wind. Depending on production, the springs may be produced either right or left wound. If you require a specific direction of wind a special spring must be produced.

If an extension spring with an exact value for one of the following parameters is required, springs must be custom-made:

- Loop type

- Loop height (LH)

- Loop position (X)

- Loop width (if the spring is to be incorporated into a tube)

- Opening at loop (m)

- Initial force (F0)