Compression Springs | Produced In Spring Steel

Range A&B. Compression springs are used in a large number of structures where compressed force is required.

Find the correct dimensions by using the filters underneath. Open the filters by clicking the downward arrow.

If you know the stock-number, please write it in the search box at the top of the page.

See quantity discount by clicking on the green basket next to the item.

We can deliver within 24 hours, if you order before 15:45 from Monday till Thursday and before 14:30 on Fridays, if the item is in stock. Orders placed Saturday and Sunday are being shipped the following Monday.

The force acumilates through the spring being compressed, and the force is released again when the spring is allowed to return to its original length. A compression spring is basically an ingenious low-tech component that can accumulate force and operate at optimal levels for a very long time, provided it is used and dimensioned correctly. Here you have a large selection of different sizes. Most ready for quick delivery!

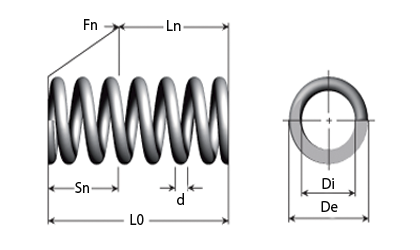

- C00570060120MIn stock: 622Material Music wired - Wire diameter (mm) 0.15De - External diameter (mm) 1.45Di - Internal diameter (mm) 1.15L0 - Unloaded length (mm) 3.05Ln - Max. loaded length (mm) 1.55Sn - Maximum travel (mm) 1.50Fn - Maximum load at Ln (N) 1.02R - Spring constant (N/mm) 0.67Range B

- C00570060190MIn stock: 213Material Music wired - Wire diameter (mm) 0.15De - External diameter (mm) 1.45Di - Internal diameter (mm) 1.15L0 - Unloaded length (mm) 4.83Ln - Max. loaded length (mm) 2.29Sn - Maximum travel (mm) 2.54Fn - Maximum load at Ln (N) 1.02R - Spring constant (N/mm) 0.39Range B

- C00570060250MIn stock: 155Material Music wired - Wire diameter (mm) 0.15De - External diameter (mm) 1.45Di - Internal diameter (mm) 1.15L0 - Unloaded length (mm) 6.35Ln - Max. loaded length (mm) 2.90Sn - Maximum travel (mm) 3.45Fn - Maximum load at Ln (N) 1.02R - Spring constant (N/mm) 0.28Range B

- C00570060310MIn stock: 9,165Material Music wired - Wire diameter (mm) 0.15De - External diameter (mm) 1.45Di - Internal diameter (mm) 1.15L0 - Unloaded length (mm) 7.87Ln - Max. loaded length (mm) 3.51Sn - Maximum travel (mm) 4.36Fn - Maximum load at Ln (N) 1.02R - Spring constant (N/mm) 0.23Range B

- C00570060380MIn stock: 549Material Music wired - Wire diameter (mm) 0.15De - External diameter (mm) 1.45Di - Internal diameter (mm) 1.15L0 - Unloaded length (mm) 9.65Ln - Max. loaded length (mm) 4.24Sn - Maximum travel (mm) 5.41Fn - Maximum load at Ln (N) 1.02R - Spring constant (N/mm) 0.19Range B

- C00570060440MIn stock: 168Material Music wired - Wire diameter (mm) 0.15De - External diameter (mm) 1.45Di - Internal diameter (mm) 1.15L0 - Unloaded length (mm) 11.18Ln - Max. loaded length (mm) 4.90Sn - Maximum travel (mm) 6.28Fn - Maximum load at Ln (N) 1.02R - Spring constant (N/mm) 0.16Range B

- C00570060500MIn stock: 380Material Music wired - Wire diameter (mm) 0.15De - External diameter (mm) 1.45Di - Internal diameter (mm) 1.15L0 - Unloaded length (mm) 12.70Ln - Max. loaded length (mm) 5.54Sn - Maximum travel (mm) 7.16Fn - Maximum load at Ln (N) 1.02R - Spring constant (N/mm) 0.14Range B

- C00570060560MIn stock: 100Material Music wired - Wire diameter (mm) 0.15De - External diameter (mm) 1.45Di - Internal diameter (mm) 1.15L0 - Unloaded length (mm) 14.22Ln - Max. loaded length (mm) 6.58Sn - Maximum travel (mm) 7.64Fn - Maximum load at Ln (N) 1.02R - Spring constant (N/mm) 0.14Range B

- C00570060620MIn stock: 262Material Music wired - Wire diameter (mm) 0.15De - External diameter (mm) 1.45Di - Internal diameter (mm) 1.15L0 - Unloaded length (mm) 15.75Ln - Max. loaded length (mm) 7.26Sn - Maximum travel (mm) 8.49Fn - Maximum load at Ln (N) 1.02R - Spring constant (N/mm) 0.12Range B

- C00570070120MIn stock: 215Material Music wired - Wire diameter (mm) 0.18De - External diameter (mm) 1.45Di - Internal diameter (mm) 1.09L0 - Unloaded length (mm) 3.05Ln - Max. loaded length (mm) 1.70Sn - Maximum travel (mm) 1.35Fn - Maximum load at Ln (N) 1.69R - Spring constant (N/mm) 1.23Range B

Material

DIN 17223 C-Wire WERKSTOFF NO. 1200

Working temperature between -30 ºC and +120 ºC

Produced in spring steel for use in dry environment.

The spring steel is not rust-resistant. If needed for use in humid/wet environment, choose from our collection of models in stainless steel here.

Range A: (The A Range consists of springs with 5 digits, ie: "12200")

IN 2098 defines the spring's dimensions based on wire thickness. Contact Sodemann Industrial Springs for further information.

DIN 2095 defines the force as the determining parameter. The number of coils may therefore vary. L0 is for guidance only and may well be longer than stated in the tables. Deviations are usually observed in a large coil ratio (Dm/d), where the spring has a thin wire in relation to the diameter. Once loaded the spring will set itself and thus achieve the correct force at the correct travel. Contact Sodemann Industrifjedre A/S for further information.

Range B: (The B Range consists of springs with 11 digits and 2 letters, ie: "C07200853000M")

On this range, the number of coils is not shown, because the spring is produced after the force as the primary measurement. Therefore the variation in wire size, through tolerance or availability, will always have an effect on the number of coils.

Fn for spring steel (music wire) is approx 12% stronger than Fn for the exact same model in stainless steel.

Calculation of spring force at a given length is travel s * R

For example:

A spring is compressed 16 mm and the spring constant is 3 N (16 mm * 3 N = 48 N)

A spring that travels 16 mm thus produces 48 N, which equates to approx. 4.8 kg.

If compression springs with a very high spring constant/carrying capacity are required, coloured die springs are recommended.

Range A: Wire up to and including 0.8 mm is closed, but unground. Wire from 1.0 mm is closed and ground.

Normally right-handed

If the springs are compressed to Ln, the spring will set itself. It will then not return to its original length, L0.

Always dimension a spring so that it delivers the desired travel and force with as little exertion as possible. This prolongs the service life of the spring. Applying maximum load to the spring will shorten its service life and cause it to become permanently distorted.